Tuam Tshoj 6 Axis 1800mm Caj Npab ncav cuag Tsis Siv Neeg Hlau MIG Vuam Robotic Arm

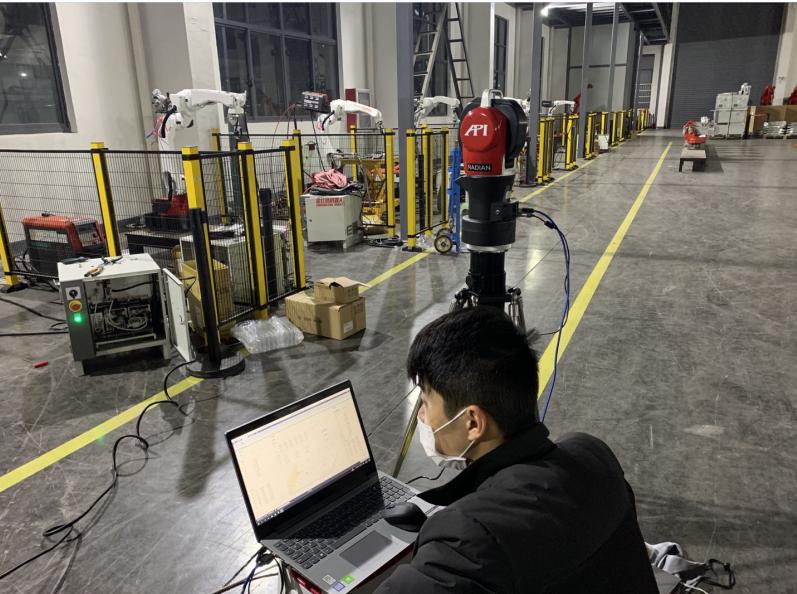

LASER CALIBRATION TEST REPOSITIONING ACCURACY

JHY siv txoj kev laser calibration los kuaj qhov rov ua qhov tseeb ntawm tus neeg hlau.Tom qab ntau qhov kev sim, qhov rov ua qhov tseeb ntawm peb cov neeg hlau yog siab dua ± 0.08mm.

Siv cov khoom lag luam zoo tshaj plaws rau cov khoom siv tseem ceeb

Robot core accessories xws li servo lub cev muaj zog, RV reducer, harmonic reducer, servo tsav thiab lwm yam siv nyob rau hauv Tuam Tshoj cov khoom lag luam sab saum toj, uas tau sim los ntawm peb lub sij hawm ntev siv los xyuas kom meej tias lawv haum rau peb cov neeg hlau.

KEV SIB THAM

Kev saib xyuas yog yooj yim, Raws li kev saib xyuas phau ntawv qhia los ntawm peb cov neeg siv khoom lawv tus kheej tuaj yeem ua haujlwm yooj yim.

Tom qab kev muag khoom lav

Txhua tus neeg siv khoom muaj nws cov pab pawg tom qab muag.Yog tias koj xav tau kev pab tom qab muag, Pls nug txhua lub sijhawm.Peb cov kws tshaj lij engineers yuav daws nws hauv lub sijhawm luv tshaj plaws.Lub ntsiab lus yog nws yog txhua yam dawb.

| Vuam tsis siv rau cov hlau me me thiab cov hlau tsis tshua muaj hlau | |||||||||

| hom | phaj | Hlau txoj kab uas hla | hauv paus kis | vuam tam sim no | vuam voltage | vuam ceev | Hu rau lub tswv yim-workpiece nrug | Gas ntws | Vuam kaum |

| T-shaped taub qab vuam | 1.0 | 0.8 ua | 2.5 ~ 3 | 70-80 | 17-18 : kuv | 8-10 | 10 | 10 ~ 15 | 45 ° |

| 1.2 | 1.0 | 3-3.5 | 85x9 0 | 18-19 ib | 8-10 | 10 | 10 ~ 15 | 45 ° | |

| 1.6 | 1.0, 1.2 | 3-3.5 | 100 ~ 110 | 18-19.5 Nws | 8-10 | 10 | 10 ~ 15 | 45 ° | |

| 2.0 | 1.0, 1.2 | 3-3.5 | 115-125 ib | 19.5-20 Nws | 8-10 | 10 | 10 ~ 15 | 45 ° | |

| 2.3 | 1.0, 1.2 | 3-3.5 | 130-140 Nws | 19.5-21.0 Nws | 8-10 | 10 | 10 ~ 15 | 45 ° | |

| 3.2 | 1.0, 1.2 | 3.5 ~ 4 | 150-170 Nws | 21-22 ib | 7.5-8 | 15 | 15 ~ 20 | 45 ° | |

| 4.5 | 1.0, 1.2 | 4.5 ~ 5 | 180-220 Nws | 21-23 ib | 6.5-7.5 hli | 15 | 15 ~ 20 | 45 ° | |

| 1.2 | 5-5.5 | 200-250 | 24-26 ib | 6.5-8 | 10 ~ 15 | 10 ~ 20 | 45 ° | ||

| 6 | 1.2 | 5-5.5 | 230-260 Nws | 25-27 ib | 6.5-7.5 hli | 20 | 15 ~ 20 | 45 ° | |

| 6 | 220-250 | 25-27 ib | 5.5-7.5 hli | 13-18 : kuv | 10 ~ 20 | 45 ° | |||

| 4-4.5 | 270-300 Nws | 28-31 ib | 10-11.5 Nws | 13-18 : kuv | 10 ~ 20 | 45 ° | |||

| 8,9 ib | 1.2, 1.6 | 6 x7 | 270-380 Nws | 29-35 ib | 6.5-7.5 hli | 25 | 20 ~ 25 | 50 ° | |

| 8 | 1.2 | 5 x 6 | 270-300 Nws | 28-31 ib | 9-10 | 13-18 : kuv | 10 ~ 20 | 45 ° | |

| 1.2 | 7 x8 | 260-300 Nws | 26-32 ib | 4.5.5 | 15 ~ 20 | 10 ~ 20 | 50 ° | ||

| 1.6 | 6.5-7 | 300-330 Nws | 30-34 ib | 5-5.5 | 15 ~ 20 | 10 ~ 20 | 50 ° | ||

| 12 | 1.2, 1.6 | 7 x8 | 270-380 Nws | 27-35 ib | 4.5-6.5 | 20 ~ 25 | 20 ~ 25 | 50 ° | |

| 1.2 | 7 x8 | 260-300 Nws | 26-32 ib | 4.5.5 | 15 ~ 20 | 10 ~ 20 | 50 ° | ||

| 1.6 | 6.5-7 | 300-330 Nws | 30-34 ib | 5 x 6 | 15 ~ 20 | 10 ~ 20 | 50 ° | ||

Nco tseg:

1. MIG vuam siv cov roj inert, feem ntau yog siv rau vuam ntawm txhuas thiab nws cov alloys, tooj liab thiab nws cov alloys, titanium thiab nws alloys, raws li zoo raws li stainless hlau thiab kub-resistant hlau.MAG vuam thiab CO2 roj shielded vuam yog tsuas yog siv rau vuam carbon steel thiab tsis tshua muaj alloy siab zog hlau.

2. Cov ntsiab lus saum toj no yog siv rau kev siv xwb, thiab nws yog qhov zoo tshaj plaws kom tau txais cov txheej txheem vuam zoo tshaj plaws los ntawm kev sim ua pov thawj.Cov kab uas hla saum toj no yog raws li cov qauv tiag tiag.